Engineering Branch Training Part 2 Steam boiler, Engineering, Marine engineering

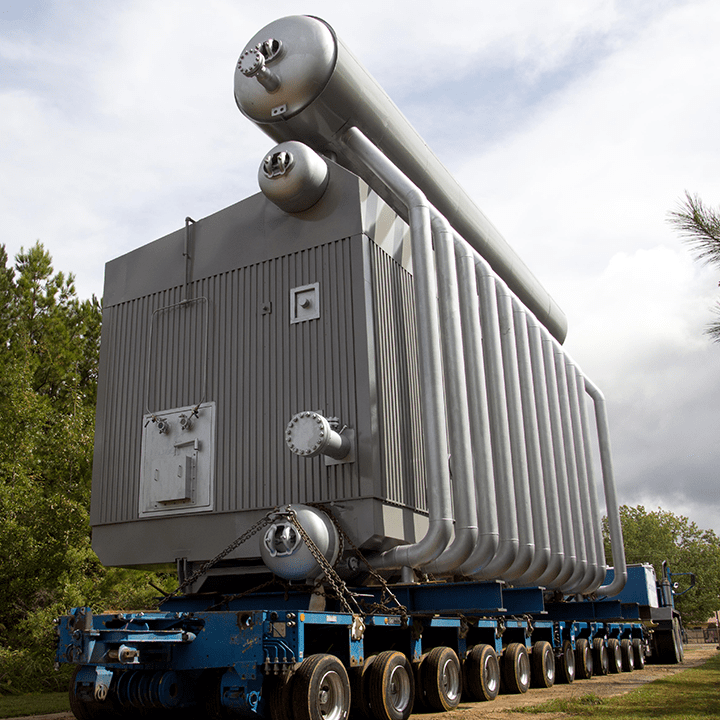

Babcock & Wilcox (B&W) is a global leader in supplying a wide range of industrial water-tube designs to meet targeted, challenging, long-lasting operational and performance goals. industrial water-tube package boilers are custom-engineered to each project's unique specifications for varying inputs and desired outputs.

Babcock wilcox hires stock photography and images Alamy

Important Point What Is Babcock and Wilcox Boiler? The Babcock and Wilcox boiler is a horizontal, externally fired, water hose, natural circulation boiler. This boiler is named after the individuals who discovered it. It was discovered in 1967 by Herman Babcock and Stephen Wilcox.

Babcock and Wilcox Boiler Parts, Construction and Working Principle

Babcock and Wilcox Boiler is a horizontal type drum axis, natural circulation, stationary, high pressure, solid fuel-fired water tube boiler. In the year of 1967, it was introduced by George Herman Babcock and Stephen Wilcox. After that Babcock and Wilcox Boiler was named by its inventor Babcock and Wilcox and till now we are using this name.

BABCOCK and WILCOX BOILER Lab Manual Engg Tutorials

Babcock and wilcox boiler working animation simple diagram construction explained water tube boiler - YouTube 0:00 / 5:04 working of babcock and wilcox boiler construction is.

Babcock and Wilcox Boiler Construction, Working, Application, Advantages and Disadvantages

Babcock & Wilcox is a single-source supplier for quality, dependability and reliability when it comes to replacement parts and services. A wide range of power plant, boiler, auxiliary and environmental equipment replacement parts and services is available. Our boiler component capabilities include: Pressure Parts Straight and bent boiler tubes

Babcock and Wilcox Lindberg Process Equipment

E101-3174 Construction Overview BWCC E101-3126 Quality Products for Power and Industry PS-482 Product and Services Line Card Renewables / Waste-to-Energy / Biomass E101-3241 Waste to Energy E101-3258 Eos Energy Storage System E101-3190 Biomass Renewable Energy Solutions E101-3261 Babcock Wilcox Solar Solutions.pdf

Babcock and wilcox boiler working animation simple diagram construction explained water tube

Top 10 Best Boiler Repair in Smithtown, NY 11787 - September 2023 - Yelp - Safehaven Home Services, Platinum Plumbing Service, PlumbKings, MKC Plumbing & Heating, GallettAir, AAA Plus HVAC, MD Plumbing & Heating, BoilersRUs, Steve Lauschus Plumbing & Heating, Amerikhomes Heating & AC

Water Tube Boiler Definition, Types, Advantages, Disadvantages, Application [Notes & PDF]

The Babcock and Wilcox Boiler, often abbreviated as B&W, is a water-tube boiler known for its reliability and efficiency in steam power generation. Invented by George Herman Babcock and Stephen Wilcox in the late 19th century, this iconic boiler design has played a pivotal role in shaping the history of industrial and power generation systems.

Babcok Wilcox Boiler

Manufacturing and Installation services for a greatly simplified, high-performing, low-emissions steam generation system. Equipment can include: Boiler Burner, including windbox, fuel skid and PRV skid Combustion air fan Ammonia injection grid (AIG) Selective catalytic reduction (SCR) reactor Economizer Deaerator Stack and more.

Babcock & Wilcox Enterprises We Offers World Class Supercritical and Ultrasupercritical

Babcock and Wilcox boiler diagram | Babcock and Wilcox boiler easy diagram |Babcock and Wilcox boiler images | Babcock and Wilcox boiler schematic diagram Advantages of Babcock and Wilcox boiler | advantage of Babcock and Wilcox water tube boiler Disadvantages of Babcock and Wilcox boiler

Introduction Of Boilers And Details Of Lancashire Boiler, Boiler, Babcock And Wilcox

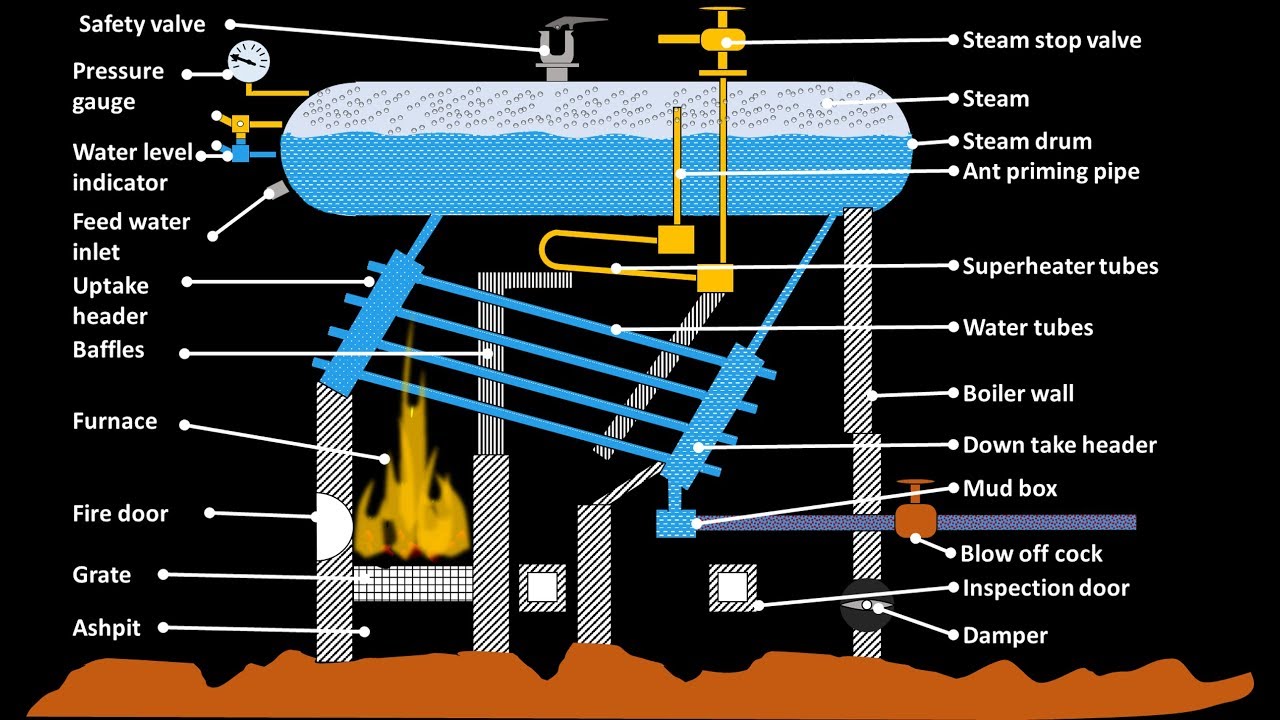

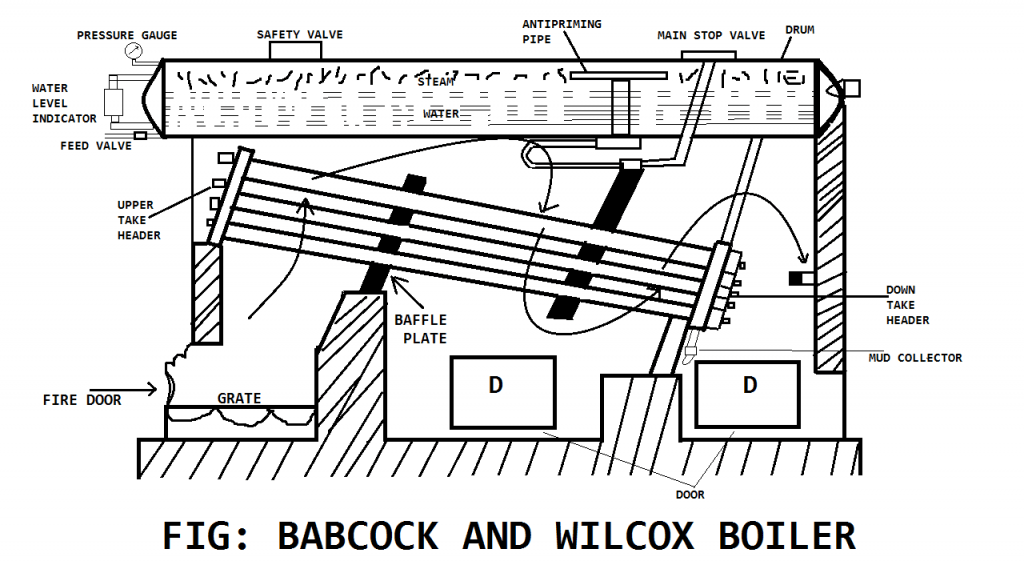

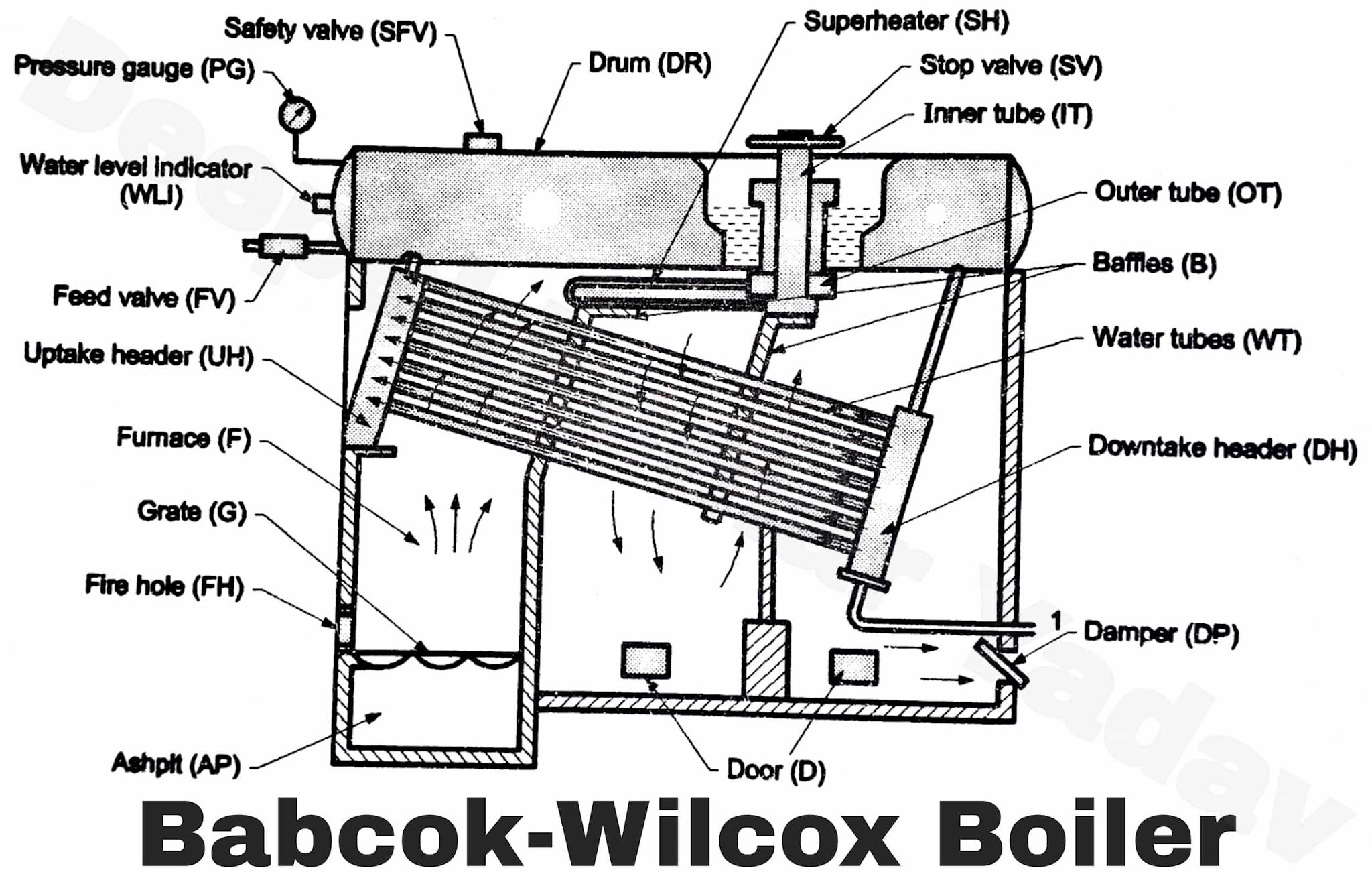

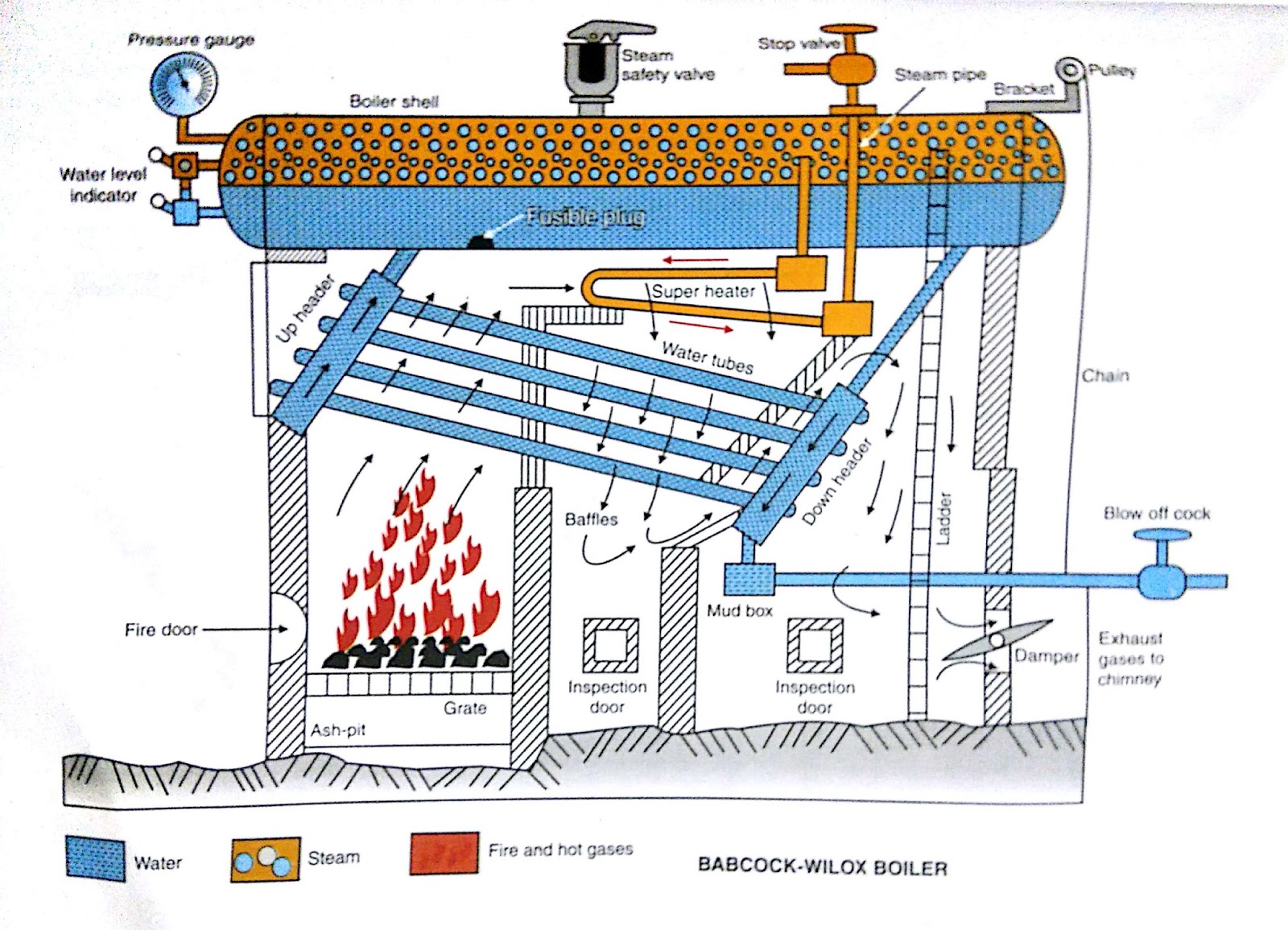

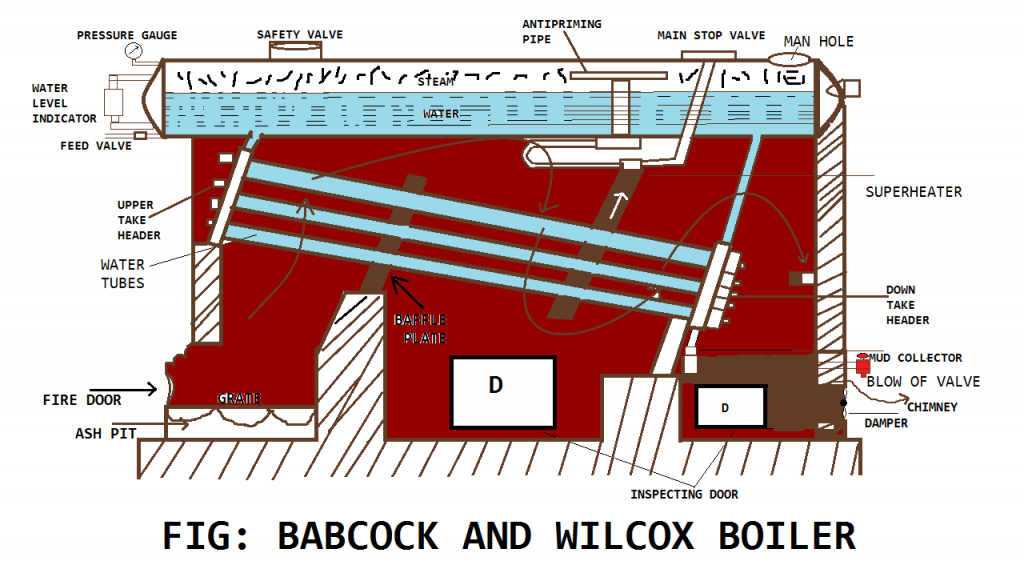

Drum diameter = 1.22 to 1.83 m Overall Length = 6.096 to 9.144 m Diameter of the Super-heater tubes = 3.84 to 5.71 cm Steaming Capacity = 40,000 kg/h (max) Diameter of the water tubes: 7.62 to 10.16 cm Efficiency = 60% to 80%. Working pressure = 140 bar (max) Schematic Diagram 1. Steam and Water Drum It is also known as Steam drum.

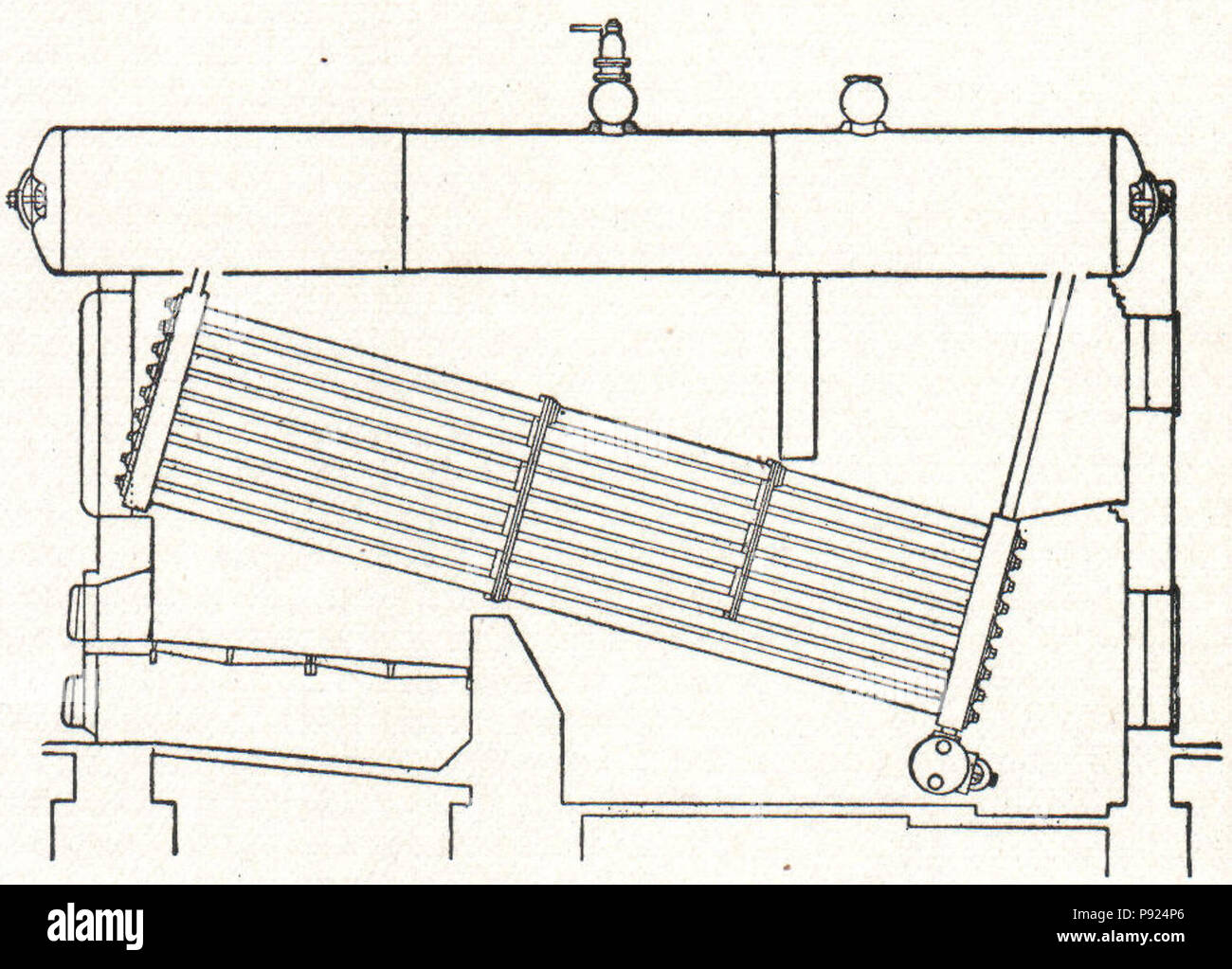

5 Babcock and Wilcox boiler Download Scientific Diagram

The baffles They are used to provide a zigzag path for the combustion gasses thus increasing the heat transfer to the water tubes. These are just a few components that are really important to know if you want to capture the working principle of the Babcok and Wilcox boiler.

Babcock and Wilcox Boiler Definition, Parts, Working, Advantages, Application [Notes & PDF]

March 26, 2022 in Thermodynamics 0 BABCOCK AND WILCOX BOILER Babcock and Wilcox Boiler is a simple water tube boiler in which water is flowing in the tube and hot gases surround them. Here we are going to study Definition, Construction or Parts, Working Principle, Application, Advantages, Disadvantages of Babcock and Wilcox Boiler in very detail.

Babcock and Wilcox Boiler Parts, Working, Advantages & More

November 15, 2023 0 Comments 11 Views Babcock and Wilcox boiler is a kind of water tube boiler, why? In this type of boiler, the hot combustion or flue gases are present outside the water-filled tubes. In a water tube boiler, almost any solid, liquid, or gaseous fuel can be burnt.

Badcock and wilcox boiler ppt file dastjuice

What is Babcock and Wilcox boiler? Babcock Wilcox boiler is a horizontal, high-pressure, natural circulation solid fuel-fired stationary water tube boiler. Babcock and Wilcox boiler was invented in 1967 by Herman Babcock and Stephen Wilcox. As you can see, This boiler's name is taken from the inventor's name. Parts of Babcock and Wilcox boiler-

Babcock and Wilcox Boiler Definition, Parts, Working, Advantages, Disadvantages, Applications

5 Babcock and Wilcox boiler | Download Scientific Diagram Fig 1 - uploaded by Dr. Ravindran S. Content may be subject to copyright. 5 Babcock and Wilcox boiler Source publication +5 Basic.